Jan 15,2026

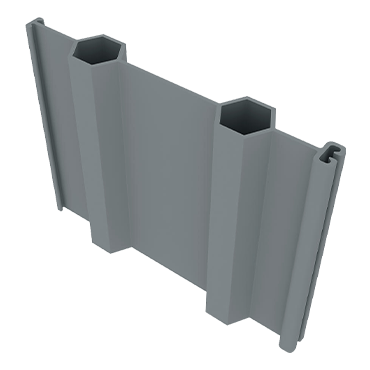

Vinyl sheet piles, also known as PVC or plastic sheet piles, are structural elements used for retaining walls, marine bulkheads, flood protection, and erosion control. Made from high-density vinyl, they offer a lightweight, corrosion-resistant alternative to traditional steel and concrete piles. Their use has grown in civil engineering, waterfront construction, and environmentally sensitive projects due to their longevity, low maintenance, and sustainable production advantages.

Understanding how vinyl sheet piles compare to steel and concrete alternatives requires an examination of multiple factors, including structural performance, installation methods, environmental impact, cost, and long-term maintenance requirements. Each material offers unique advantages and limitations depending on the application and environmental conditions.

Material Properties and Structural Performance

Vinyl sheet piles are made from high-density PVC with additives that improve strength, UV stability, and flexibility. Unlike steel, vinyl does not corrode when exposed to water or chemicals, making it ideal for marine and coastal environments. While vinyl has a lower structural strength compared to steel or reinforced concrete, it is often sufficient for moderate retaining wall heights and low- to medium-load applications.

Strength Comparison

- Steel sheet piles have the highest tensile strength and can support tall, heavily loaded structures.

- Concrete sheet piles provide excellent compressive strength and rigidity but are heavy and difficult to handle.

- Vinyl sheet piles offer moderate strength, suitable for low to medium-height retaining walls and flood control applications.

Corrosion Resistance and Environmental Durability

One of the most significant advantages of vinyl sheet piles is their resistance to corrosion. Unlike steel, vinyl does not rust or degrade when exposed to water, salt, or chemicals. Concrete is also durable but can suffer from cracking, spalling, or reinforcement corrosion over time, especially in marine environments. Vinyl’s inert nature ensures a long lifespan, often exceeding 50 years in harsh conditions without protective coatings or regular maintenance.

Environmental durability includes resistance to UV radiation and temperature fluctuations. High-quality vinyl sheet piles contain UV stabilizers that prevent brittleness and discoloration from sun exposure. In contrast, steel requires protective coatings or galvanization, and concrete may need sealing or treatment to prevent surface erosion.

Installation Methods and Practical Considerations

Vinyl sheet piles are lightweight and flexible, which simplifies transportation and installation. They can often be driven with smaller equipment, reducing site preparation costs and noise. Interlocking designs allow for quick assembly, even in constrained or environmentally sensitive areas.

Installation Comparisons

- Steel sheet piles require heavy equipment and can produce noise and vibration during driving.

- Concrete piles are heavy, demanding cranes and careful handling to prevent cracking or damage.

- Vinyl piles are easier to transport and install, with minimal environmental disruption.

Maintenance Requirements and Longevity

Maintenance is a key differentiator between vinyl, steel, and concrete sheet piles. Steel requires periodic inspections and anti-corrosion coatings. Concrete may need patching or crack repair over time. Vinyl sheet piles, in contrast, are virtually maintenance-free, with no painting, coating, or protective treatments required. This reduced maintenance translates into lower life-cycle costs and less operational downtime.

Cost Analysis and Lifecycle Value

Initial material costs for vinyl sheet piles are generally lower than for coated steel but can be slightly higher than basic concrete options depending on thickness and design. However, when considering transportation, installation, maintenance, and long-term durability, vinyl often offers superior lifecycle value. The combination of lightweight handling, corrosion resistance, and minimal upkeep provides a cost-effective solution for many low- to medium-load retaining structures.

Environmental Impact and Sustainability

Vinyl sheet piles have a smaller environmental footprint compared to steel and concrete in several respects. Manufacturing processes consume less energy, and the piles are fully recyclable at the end of their service life. Reduced maintenance and absence of corrosion-resistant coatings minimize environmental pollution. In comparison, steel production is energy-intensive, and concrete manufacturing generates significant CO₂ emissions.

Comparing Applications: Steel, Concrete, and Vinyl

| Material | Ideal Applications | Key Advantages | Limitations |

| Steel Sheet Piles | Large retaining walls, marine docks, deep excavations | High strength, reusable, supports heavy loads | Corrosion risk, high installation cost |

| Concrete Sheet Piles | Flood walls, quay walls, heavy-load industrial sites | High compressive strength, rigid, durable | Heavy, difficult to install, susceptible to cracking |

| Vinyl Sheet Piles | Moderate-height retaining walls, erosion control, environmentally sensitive sites | Corrosion-resistant, lightweight, low maintenance | Lower structural strength, limited heavy-load capacity |

Key Considerations for Selecting Vinyl Sheet Piles

When deciding whether vinyl sheet piles are suitable for a project, consider the following factors:

- Wall height and load-bearing requirements

- Soil type and water table conditions

- Environmental exposure, including saltwater, chemicals, and UV radiation

- Installation equipment and accessibility

- Long-term maintenance and lifecycle cost considerations

Conclusion

Vinyl sheet piles provide a practical, cost-effective, and environmentally friendly alternative to traditional steel and concrete sheet piles in many applications. While their structural strength is lower, they excel in corrosion resistance, ease of installation, low maintenance, and lifecycle sustainability. By evaluating project-specific requirements such as load, wall height, and environmental conditions, engineers and designers can determine whether vinyl sheet piles offer the best combination of performance, cost efficiency, and long-term durability for their construction projects.

English

English 中文简体

中文简体